The widely-used 3D printing technologies can be broadly divided into two categories – consumer and industrials. Consumer 3D printers are found in homes, offices, and educational institutions. At the same time, enterprises from various sectors use industrial-grade 3D printers to switch from subtractive or conventional manufacturing to additive manufacturing.

Fused Deposition Modeling (FDM) is a 3D printing technology that is used widely by individuals and enterprises. The usage statistics posted on Statista suggest that FDM is currently the most commonly used 3D printing technology.Also, FDM drives the steady and consistent growth of the global 3D printing market.

What is FDM 3D Printing?

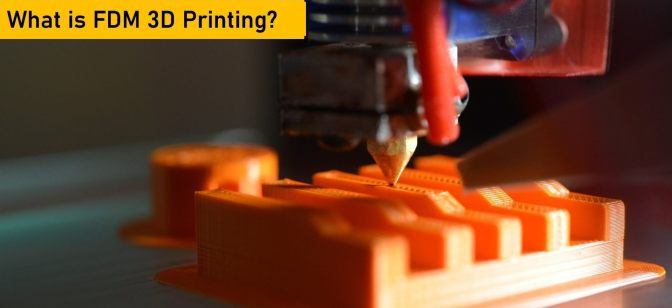

Like other 3D printing technologies, FDM produces solid parts from digital files. Also, it creates the parts by depositing materials layer by layer. But FDM, unlike other 3D printing technologies, creates parts using the material extrusion method.

FDM 3D printers are designed with nozzles through which the thermoplastic filaments are extruded. The heated nozzle melts the filament and deposits the melted filament onto the build platform layer by layer. The material extrusion method makes FDM scores over other 3D printing technologies in several categories – ease of use and cost-efficiency.

How Do FDM 3D Printers Work?

While planning an FDM 3D printing project, engineers have the option to choose from a wide range of thermoplastic materials. They fed the thermoplastic filament into the 3D printing machines in the shape of plastic threads through a nozzle.

They melt the filament by heating the nozzle. The heated nozzle deposits the melted filament layer by layer over the build platform. The thermoplastic cools and solidifies gradually as the nozzle moves across the base. Also, they form a solid bond with the earlier layer.

Once a layer is printed, the build platform descents or ascents to facilitate the formation of the next layer. These steps are repeated till the printer created the part fully according to the digital 3D model.

Engineers always choose the FDM 3D printer according to the build size and layer height. Also, they customize the FDM 3D printing process by adjusting important parameters like build speed, nozzle temperature, cooling fan speed, and build platform temperature.

What are the Material Options for FDM 3D Printing?

FDM beats other 3D printing technologies in the category of material options. While planning the FDM 3D printing process, engineers have the option to choose from a wide range of feedstock materials or filaments. For instance, they can choose from widely-used polymers like PLA, PET, ABS, Nylon, TPU, and PC.

Also, they can improve the physical properties of the filament by opting for composite materials like Tough PLA which is produced by combining PLA and ABS. Likewise; they can make 3D-printed parts effective in resisting mechanical stress by opting for fiber-filled materials.

Leading manufacturers have been producing innovative FDM 3D printing filaments regularly. The affordability and availability of these polymer and composite filaments contribute hugely toward making FDM the most commonly used 3D printing technology.

What are the Common Applications of FDM 3D Printing?

Concept Modeling

Engineers use concept models to understand precise requirements or identify potential issues before starting production. FDM 3D printing machines and materials help them create concept models without putting in extra time and resources.

Rapid Prototyping

Engineers test a concept or evaluate a process by creating prototypes. They use FDM 3D printers to produce preliminary versions of a product in a short amount of time. Also, they leverage the printer to make several changes to the prototype during the testing process.

Low-Volume Manufacturing

FDM 3D printing helps manufacturers switch from subtractive manufacturing to additive manufacturing. A manufacturer can use industrial-grade FDM 3D printers to facilitate low-volume production of complex parts without using conventional tooling.

End Part Fabrication

Many companies these days prefer printing end parts to producing end parts. They leverage FDM 3D printing technology to reduce the time and costs required to fabricate end parts. Also, they can boost the part’s quality and durability using the appropriate FDM 3D printing material.

Manufacturing Tool Development

FDM 3D printing creates opportunities for engineers to produce next-generation manufacturing tools. Engineers can reduce the time and resources required to fabricate jigs, fixtures, and other manufacturing tools using industrial-grade FDM 3D printers.

Making Consumer Products

Access to FDM 3D printers creates opportunities for students and hobbyists to produce a variety of consumer products. Students showcase their creativity and skill by producing innovative toys, home decor, and gift items using FDM 3D printers. At the same time, hobbyists use FDM 3D printing technologies to create new use cases and meet emerging needs regularly.

What are the Pros and Cons of FDM 3D Printing Technology?

Pros

- Less complex than other 3D printing technologies

- Less expensive than other 3D printing technologies

- Availability of a wide range of FDM 3D printing materials

- Option to reuse FDM 3D printing materials

- Perform post-processing activities without investing in specialized tools and expensive liquids.

- FDM 3D printers are easy to store and move

- New-age FDM 3D printers support cloud server printing

Cons

- FDM printers need more time to produce a part as they print layer by layer.

- Engineers have to opt for multidirectional printing to unidirectional printing to make stronger parts.

- Often misalignment or weak adhesion of layers results in print failure.

- Engineers must clean and maintain the FDM 3D printer regularly to prevent nozzle clogging.

- Users can improve safety only by installing the FDM 3D printer in a well-ventilated environment.

Conclusion:

FDM is currently more popular than other 3D printing technologies. Enterprises invest in industrial-grade FDM 3D printers to produce product prototypes and functional parts. At the same time, desktop FDM 3D printers are used widely by students, engineers, and hobbyists. Also, many individuals and enterprises these days avail of FDM 3D printing services to produce physical objects by overcoming constraints related to time, resources, and skills.